Description

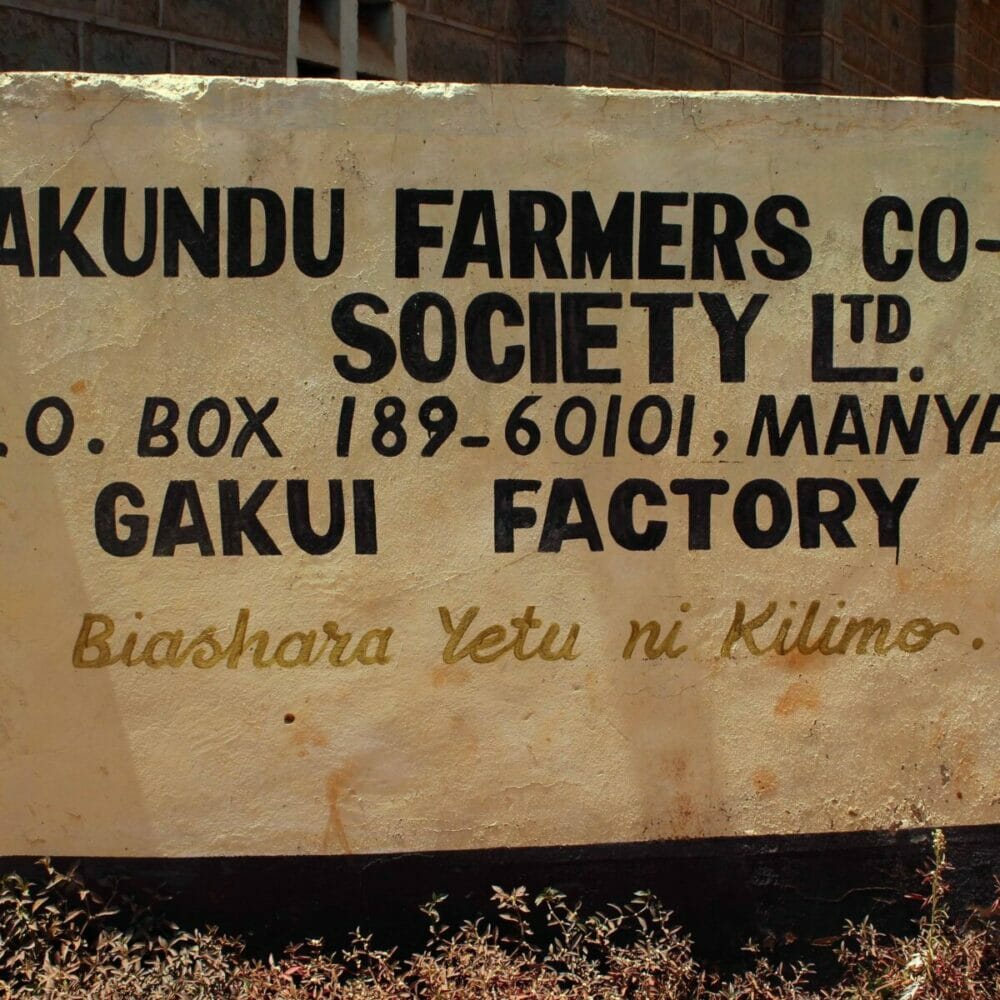

Gakui

On the verdant slopes of Mount Kenya lies the Gakui Coffee Factory. Built in 1996, this coffee cooperative recently acquired computers with internet access, allowing them to provide their members with market data and expedite payment processing for farmers. Thanks to these technological advances, Gakui has been able to access agricultural inputs and enlist the help of agronomists who advise them on how to maximize their production. Amidst a stunning mountain landscape, Gakui is always striving to improve and offer the best coffee to its customers.

The Gakui Coffee Factory is a place where the aroma of coffee blends with the fresh mountain breeze. Under the wise guidance of the factory manager, the cooperative's staff is dedicated to tasks such as weighing and grading the coffee, paying farmers, and addressing their complaints.

In addition, the factory offers incentives such as agricultural inputs on credit and cash advances to farmers. This cooperative is a place where technology combines with tradition to produce high-quality coffee.

The region where Gakui is located has a temperate climate, with moderate bimodal rainfall and temperatures ranging from 13 to 24 degrees Celsius. The red volcanic soil is ideal for growing the cooperative's main coffee varieties, including SL28, Batian, SL34, and Ruiru 11.

At Gakui, coffee production is an art carried out with passion and dedication, and the end result is delicious, high-quality coffee.

Process

At the Gakui factory, each coffee bean is treated with the care and respect it deserves. The coffee cherries are washed and pulped to separate the dense beans from the immature "mbuni" (floating beans) using water flotation.

The densest grains sink and are sent through channels to the fermentation tank, where the first phase of fermentation begins, lasting about 24 hours. Once complete, the grains are washed again and sent to the secondary fermentation tank, where they remain for another 12-24 hours.

Every stage of the process at Gakui is designed to achieve the best coffee flavor. From the careful selection of cherries to controlled fermentation, every step is important in producing high-quality coffee.

Once the fermentation process is complete, the coffee beans enter the washing channels at the Gakui brewery. Here, the floating beans are further separated, and the dense beans are cleaned of the mucilage that covers them. The washed beans are then transferred to soaking tanks where they remain submerged in clean water for another 24 hours.

This soaking process allows the amino acids and proteins in the cellular structure of each bean to develop, resulting in higher acid levels in the coffee, which translates into more intense acidity and fruity flavors in the cup. This process is believed to contribute to the distinctive flavor profiles of Kenyan coffees.

The Gakui brewery has built numerous filtration tanks to treat the water used in processing, preserving the quality of local water. The beans are then transferred to initial drying tables, where they are laid out in a thin layer to allow for rapid removal of approximately 50% of the moisture.

This initial drying stage can last about six hours before the beans are picked and placed in thicker layers for the remaining 5-10 days of the drying period. Once dried, the beans are delivered to a private mill where they are turned into parchment coffee. The Gakui factory is a place where technology and tradition combine to produce high-quality coffee with a distinctive flavor.

Pre-financing of farmers

The cooperative's farmers have benefited from pre-financing, allowing them to purchase the necessary inputs to carry out their work. With the help of Coffee Management Services, the factory has been able to offer training and access to seminars on Good Agricultural Practices to improve coffee production. Furthermore, the factory's commitment to paying high returns for the coffee they produce has helped farmers achieve a brighter future.

But it's not just about improving coffee production; the factory has also demonstrated its commitment to the environment. By excavating wastewater far from the water source, it prevents water pollution. Furthermore, the society encourages its members to plant trees on their farms, demonstrating its concern for preserving the environment and promoting sustainability in agriculture.

It's a success story, where pre-financing has been a crucial tool for farmers, who, thanks to it, have been able to improve their living conditions and contribute to a better future for all.